So it was finally time. We bought a box truck. A post shared by Andrew (@greenmachinefarm) on Mar 5, 2017 …

Tag: small business

Big Wheels

It’s that time of year again, mostly spent inside where it’s warm. That and the new year is kicking off …

Square for Meat: still not there yet

Before we did our first market we went ahead and ordered up a pair of Square credit-card readers to use …

Hooray! Oh No!

We’ve been looking for another farmers market to attend next year. We were hoping to land another market in the …

Chicken economics – ranger vs cornish

So I wrote earlier about the results of our first experimental batch of red ranger chickens, but I’d like to …

Farmers Market Trailer: Part 2

Amidst the flurry of activity that is a new farm in the beginning of spring, we have managed to get …

Farmers Market Trailer: Part 1

Well the animals are all here now, so it’s time to get all the stuff for the farmers markets in …

Farm Paperwork 2

I got a big manilla envelope in the mail today from the Minnesota Department of Agriculture. Turns out they sent …

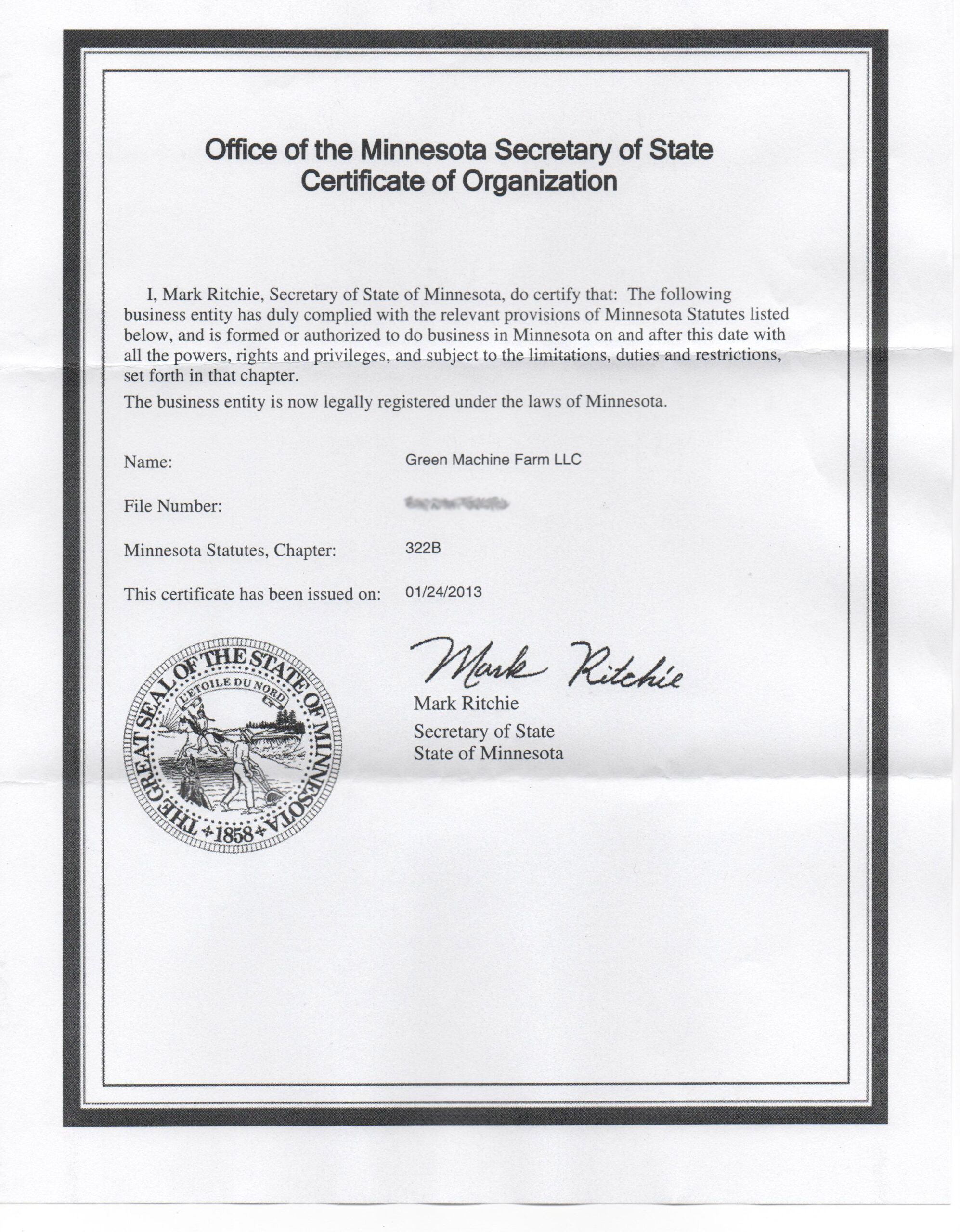

It’s Official

Hooray! We legally exist!

Farm Paperwork

It’s been a joyous day here at the farm. It’s the new year, we’re starting a new farm, farmers markets …